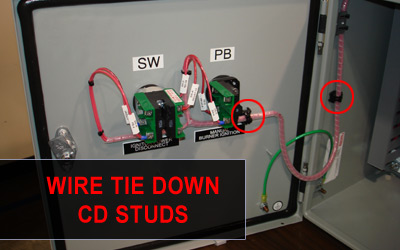

CD Wire Tie Down Stud - Application and Installation Video

The CD Wire Tie Down Stud is designed specifically for quick and rugged wire security. Wire bundles up to 1 inch in diameter can be neatly welded into place within milliseconds, providing a permanent worry-free wire maintenance system.

The Wire Tie Down Stud is an aesthetic and reliable alternative to traditional screw or adhesive fasteners.

Because the Wire Tie Down Studs are Stud Welded into place, eliminating the need for drilling holes or glue, they provide a secure installation that will not break, loosen or weaken over time, with a pull off that exceeds the capability of a typical 3/16 inch nylon cable tie.

Wire Tie Down Studs are ideally suited for any wire assembly, from heavy duty construction equipment to wire management in industrial control boxes and telephone junction boxes.

The stud is a Capacitor Discharge, CD Weld Stud, and is installed with traditional CD Stud Welding equipment. The stud is equivalent to a U.S. number 10 fastener. The Wire Tie Stud is compatible with any CD welder capable of welding a number 10 stainless steel or aluminum fastener.

| For a quote or to order, please specify: | |

|---|---|

| Product Code: | Material: |

| CTB | Specify |

| STUD | ||

|---|---|---|

| MATERIAL | ALUMINUM | STAINLESS STEEL |

| Grade - 5000 Series | AISI grade | |

| 302 HQ | ||

| MECHANICAL PROPERTIES | Tensile - 45,000 psi (min.) | Tensile - 85,000 psi (min.) |

| Yield - 40,000 psi (min.) | ||

| Yield - 25,000 psi (min.) | ||

| SIZE | Equivalent to U.S. #10 | Equivalent to U.S. #10 |

| SADDLE | |

|---|---|

| MATERIAL | Nylon 6/6 |

| NYLON 6/6 PROPERTIES | ||||

|---|---|---|---|---|

| PROPERTY | ASTM METHOD | TEST CONDITION | UNITS | NYLON 6/6 |

| Tensile Strength | D638 | +73°F; 50% RH | kpsi | 11.2 |

| Elongation at Break | D638 | +73°F; 50% RH | % | >=300 |

| Yield Strength | D639 | +73°F; 50% RH | kpsi | 8.5 |

| Shear Strength | D732 | Dry as Molded (DAM) | kpsi | 9.6 |

| Deformation Under Load | D621 | 2,000 psi; +122°F; DAM | % | 1.4 |

| IZOD Impact | D256 | +73°F; 50% RH | ft lb/in | 2.1 |

| Tensile Impact Strength | D1822 | +73°F; Long Specimen; DAM | ft lb/in | 240 |

| Melting Point | D789 | Fisher-Johns | °F | 491 |

| Thermal Linear Expansion | D696 | DAM | in/in/°F | TBD |

| Thermal Conductivity | -- | DAM Conche-Fitch | BTU-in/h/ft/°F | 1.7 |

| Brittleness Temperature | D746 | 50% RH | °F | -85 |

| Oxygen Index | D2863 | DAM | %0 | 28 |

| Oxygen Index | D2864 | 50% RH | %0 | 31 |

| UL Flammability | UL 94 | DAM | -- | V-2 |

| UL Flammability | UL 95 | 50% RH | -- | V-2 |

| NYLON 6/6 NBS SMOKE GENERATION | ||||

|---|---|---|---|---|

| SAMPLE THICKNESS | UL FLAMMABILITY | ENERGY SOURCE | SPECIFIC OPTICAL DENSITY | |

| AT MAXIMUM SMOKE ACCUMULATION | AT 2 MINUTES | |||

| 1/16" | 94 V-2 | Radiant (2.5 watts/sq.cm) | 13 | 0 |

| 1/8" | 94 V-2 | Radiant Plus Flaming Gas Jets | 26 | 1 |

| NYLON 6/6 TEMPERATURE INDEX | |||

|---|---|---|---|

| MINIMUM THICKNESS | TEMPERATURE INDEX | HOT WIRE (sec) | |

| ELECTRICAL (°C) | MECHANICAL W/O IMPACT (°C) | ||

| 0.028 | 125 | 65 | 11.8 |

| 0.058 | 125 | 85 | 15.0 |

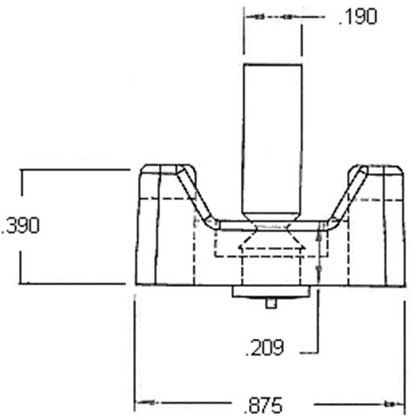

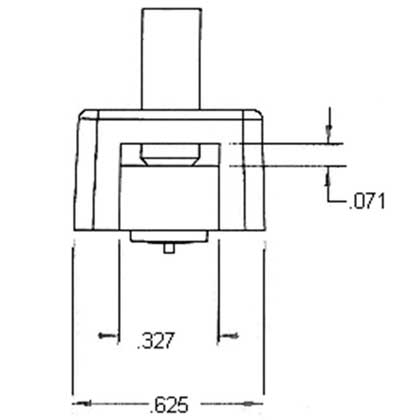

| NYLON WIRE TIE CD STUD - MECHANICAL DIMENSIONS | ||

|---|---|---|

| INCH | MM | |

| HEIGHT | 0.390 | 9.90 |

| LENGTH | 0.875 | 22.22 |

| WIDTH | 0.625 | 15.87 |

| SLOT HEIGHT | 0.090 | 2.29 |

| SLOT WIDTH | 0.325 | 8.26 |

WIRE TIE CD STUD - MECHANICAL DIMENSIONS IN INCHES

| CHEMISTRY (%) | |

|---|---|

| C | 0.017 |

| S | 0.001 |

| Cr | 17.5 |

| Mo | 0.05 |

| Mn | 0.83 |

| Si | 0.32 |

| Ni | 9.54 |

| Cu | 3.07 |

| P | 0.024 |

| Co | Trace |

| N | PPM 155 |

| Fe | Remainder |