Stud welding is a complete one-step fastening system, using fasteners called weld studs. Weld studs come in a variety of designs, threaded, unthreaded, tapped, etc., sizes and shapes for a wide range of applications.

A weld stud can be end-joined to a metal work piece instantaneously for a high quality, high strength permanent bond. (View video demonstration.)

The base metal and the welded stud fastener do not need to be the same material. For example these combinations can be welded together - brass to copper, brass to steel, copper to steel and similar combinations.

Stud welding is less expensive than other fastening methods and can used in locations which do not allow the use of other fasteners. Weld studs can be installed by one man, working on one side of the work piece, in less than a second.

There are many reasons why the stud welding process is superior over other fastening systems.

The equipment required for stud welding is composed of the following:

In most systems, the power supply and controller are combined as one component called the "Welder".

Two stud welding methods are available - Arc Stud Welding and Capacitor Discharge (CD) Stud Welding.

The stud welding method used depends on the type of stud fastener that is needed, based on the application and the base metal the weld stud fastener well be welded to.

Arc Stud Welding is generally used to weld large diameter fasteners to rougher and thicker base metals.

(See our Arc Stud Welder Selection Guide)

Arc Weld Studs may be almost any shape and there are literally hundreds of designs, however they must have one end of the fastener designed for Arc welding equipment.

Mild steel, stainless steel and aluminum are applicable materials for Arc welding.

Step 1.

A fastener and ceramic ferrule are firmly placed against the work surface under spring tension in the stud welding gun.

Step 2.

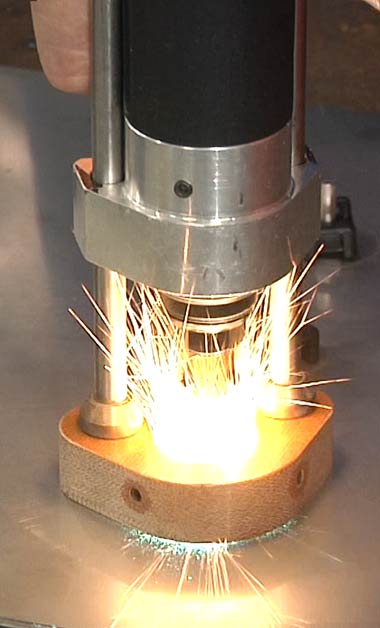

Upon triggering, the weld gun automatically lifts the fastener from the base metal and initiates a controlled electric arc which melts the end of the stud fastener and a portion of the base metal.

Step 3.

A ceramic arc shield concentrates the heat and retains the molten material in the weld area for maximum weld strength and reliability.

Step 4.

At the precise moment the fastener and the parent metal become molten, the fastener is automatically plunged into the work surface by the stud welding gun. The metal solidifies and a high quality fusion weld is completed.

| RECOMMENDED MINIMUM BASE METAL THICKNESS | ||||

| STUD WELD BASE DIAMETER | STEEL | ALUMINUM | ||

| WITHOUT BACKUP | WITHOUT BACKUP | WITH BACKUP | ||

| (in.) | (in.) | (gauge) | (in.) | (in.) |

| 0.187 0.250 | 0.0359 0.0478 | 20 18 | 0.125 0.125 | 0.125 0.125 |

| 0.312 0.375 | 0.0598 0.0747 | 16 14 | 0.187 0.187 | 0.125 0.187 |

| 0.437 0.500 | 0.0897 0.1196 | 13 11 | 0.250 0.250 | 0.187 0.250 |

| 0.625 0.750 | 0.148 0.187 | 9 | ||

| 0.875 1.000 | 0.250 0.375 | |||

Capacitor Discharge Stud Welding is generally used to weld smaller diameter fasteners to thin base metals.

(See our CD Stud Welder Selection Guide)

Since the entire weld cycle is completed in milliseconds, welds can be made without pronounced distortion, burn-through or reverse side discoloration. As long as one end of the fastener is designed for CD welding equipment, CD Studs can be manufactured in almost any shape.

Step 1.

The fastener is placed against the workpiece. Most CD studs have a special tip which provides precise weld-time control, for consistent, automatic welds.

Step 2.

The weld gun is activated and stored energy is discharged through the fastener melting the full diameter of its base and a portion of the parent material.

Step 3.

Spring-loading forces the fastener into the molten metal.

Step 4.

The fastener is held in place as the molten metal solidifies and instantly creates a high quality fusion weld.

Step 1. - Load

A weld stud fastener is manually or automatically inserted into the stud welding gun.

Step 2. - Position

The Stud Welding Gun is positioned into firm contact with the work surface.

Step 3. - Fire

The stud welding gun is activated and the fastener is welded in a fraction of a second. The weld between the fastener and base metal develops full strength instantly.

Installation of flanged aluminum CD studs with Sunbelt Pro-C 1000, VZB Feeder Bowl and PHM-500 Lift / Gap Stud Welding Gun, for rapid, high quality welds.

| ARC | CAPACITOR DISCHARGE | |||||||||||

| MATERIAL | Standard in low carbon steel and 302/304/305 stainless. Aluminum, monel, inconel, and other grades of stainless steel are available. | Standard in low carbon steel, 302/304/305 stainless, and ll00, 6061, & 5000 series aluminum. Brass and other grades of stainless steel are also available | ||||||||||

| PLATING | Cadmium to ASTM-A165 type TS, zinc to ASTM-B 633 (formerly A 164) and other platings are available. Non-weldable plating is removed from the weld end to avoid contamination of the weld | Copper plating is standard. Cadmium, Nickel, Zinc and other platings are available. | ||||||||||

| ANNEALING | Low carbon steel can be annealed to a maximum of 75 Rockwell B and stainless steel to a maximum of 90 Rockwell B. | All low carbon steel and stainless steel studs are annealed where required. | ||||||||||

| THREADS | UNC-2A is standard for external threads prior to plating and UNC-2B for internal threads. Metric and other thread sizes are available. | UNC-2A is standard for external threads prior to plating and UNC-2B for internal threads. Metric and other thread sizes are available. | ||||||||||

| WELD BASE | 1/4" dia. and over have solid flux. Diameters under 1/4'are standard pointed, and flux is optional. | Flanged, small flanged, and nonflanged are available. | ||||||||||

| STUD LENGTH | SUNBELT arc stud length designations are BEFORE WELD. AFTER WELD lengths are shown in the table below.

| CD studs have no appreciable length reduction after welding. | ||||||||||

| FERRULES | All orders include ferrules when they are required. | Does not apply to CD. |

Weld Studs fasteners are used in a wide variety of industries: